+971 2 551 0325, +971 50 441 5348

+971 2 551 0325, +971 50 441 5348

glfsteel@emirates.net.ae

glfsteel@emirates.net.ae  +971 2 551 0325,+971 2 551 0098, +971 50 441 5348 (Only For Sales Enquiries)

+971 2 551 0325,+971 2 551 0098, +971 50 441 5348 (Only For Sales Enquiries) +971 2 551 0325, +971 50 441 5348

+971 2 551 0325, +971 50 441 5348

glfsteel@emirates.net.ae

glfsteel@emirates.net.ae  +971 2 551 0325,+971 2 551 0098, +971 50 441 5348 (Only For Sales Enquiries)

+971 2 551 0325,+971 2 551 0098, +971 50 441 5348 (Only For Sales Enquiries)

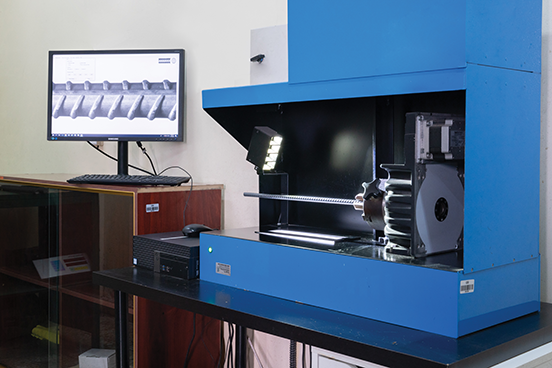

At Gulf Steel, quality is a visible outcome of best practices rigorously followed in letter and spirit. State of the art technologies and industry guidelines are key inputs in achieving this goal. The quality control department is well equipped with superior computerized monitoring and testing systems and the Engineering and R&D Division continuously strives towards the betterment of product quality.

Gulf Steel has internalized and practices Total Quality Management (TQM) systems at all stages of production\

We’re proud to be certified by Dubai Central Laboratory and CARES, U.K. for BS Standard, whilst strictly adopting BS standards.

In addition certification for ISO 6935 from Kuwait.

Our Quality Management System has been certified by CARES , U.K. We are also certified by TUV Nord for ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 and ISO 50001:2018.

Gulf Steel is fully equipped with the best-in-class equipment required for quick testing and reporting.

Gulf Steel produces high-grade TMT construction bars. The mill is technologically advanced. Due to the low carbon content and strict quality control, the TMT process bars do not lose strength at the weld joints, are highly flexible and provide top-grade elongation. The special design of the bars allows for excellent bonding properties and longer life.

State-of-the-art facilities