+971 2 551 0325, +971 50 441 5348

+971 2 551 0325, +971 50 441 5348

glfsteel@emirates.net.ae

glfsteel@emirates.net.ae  +971 2 551 0325,+971 2 551 0098, +971 50 441 5348 (Only For Sales Enquiries)

+971 2 551 0325,+971 2 551 0098, +971 50 441 5348 (Only For Sales Enquiries) +971 2 551 0325, +971 50 441 5348

+971 2 551 0325, +971 50 441 5348

glfsteel@emirates.net.ae

glfsteel@emirates.net.ae  +971 2 551 0325,+971 2 551 0098, +971 50 441 5348 (Only For Sales Enquiries)

+971 2 551 0325,+971 2 551 0098, +971 50 441 5348 (Only For Sales Enquiries)

Steel plays a vital role in the construction industry, forming the very core of every structure. Whether you are building multi-storeyed structures, houses, bridges, or any other structure, steel rebars play a significant part in their construction. Whatever the nature of the building, the longevity of the structure is fortified only with reinforcement steel bars. Therefore, when you buy steel bars for a structure, you must conduct adequate research to safeguard the life of your system. Various types of rebars are available where unique manufacturing processes are used to give them high tensile strength and ductility. Gulf Steel is a leading manufacturer of rebars in the UAE, producing high-quality deformed steel bars. Whatever the scale of the project, choosing the most suitable TMT bars with appropriate grading is essential to complete the construction successfully. Here are some crucial things you must consider before buying reinforcement steel bars.

Controlled manufacture of steel boosts strength and lowers its impurity. Due to increased impurities, steel tends to lose strength in extremely hot or cold environments. The rebars must remain ductile to ensure energy absorption above typical limits. This process makes buildings resistant to earthquakes and other natural disasters. Besides, several newer technologies provide high-quality bars, which give more strength than ordinary steel bars. Gulf Steel uses the TMT or thermos-mechanical treatment process to manufacture steel rebars in 8 mm to 32 mm widths and lengths ranging from 6 Mts to 12 Mts.

It is imperative to check the grades of the steel bars you use, especially if you are constructing a building in an area prone to earthquakes. Choosing high-grade bars that have undergone a refining process is important, which bestows excellent quality. Specific chemical formulations produce various bars that confer tensile strength, yield strength, and durability. For instance, civil construction always recommends employing Fe-500 and Fe-500D grades.

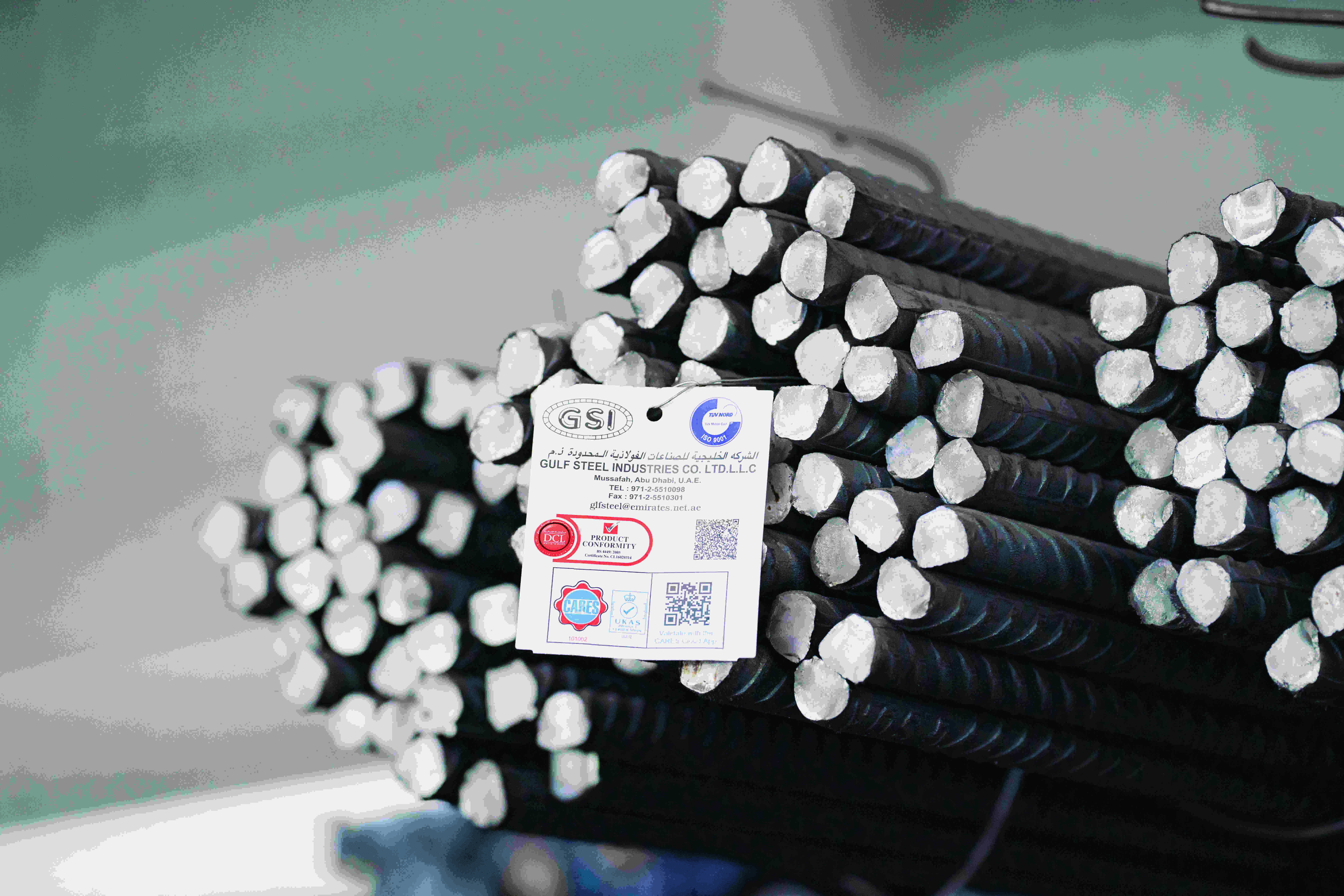

Always choose reputable brands over others because their rebars adhere to international standards. Certification gives a clear indication of the company’s reputation and the longevity and quality of the product. Gulf Steel is a certified rebar producer in the UAE committed to upholding the quality and durability of our products.

Cracks in construction can compromise the building’s safety and structural integrity. Adopt highly flexible rebars that withstand high-intensity shocks, seismic strains, concrete permeability or creep movement. Structures can be significantly stronger when galvanised TMT rebars and reinforced concrete are utilised.

Tensile strength testing is one of the most crucial steps that has to be undertaken to ensure the yield quality of the rebar. It is carried out to determine how the material responds to force. Choose a well-known brand, such as Gulf Steel, that offers all proper quality checks before delivery of the rebars.